The Vertical Form Fill Seal (VFFS) Packaging Machine is an automated solution designed to enhance efficiency and consistency in packaging operations. By forming, filling, and sealing packages in a vertical orientation, VFFS machines are ideal for a wide range of products across various industries.

High-Speed Operation: Capable of producing up to 100 packages per minute, significantly increasing production rates and reducing manual labor.

Versatility: Suitable for packaging solids, powders, granules, and liquids. The machine can handle various packaging materials, including polyethylene, polypropylene, and laminated films.

Precision and Consistency: Ensures accurate product filling and airtight sealing, minimizing waste and maintaining product quality.

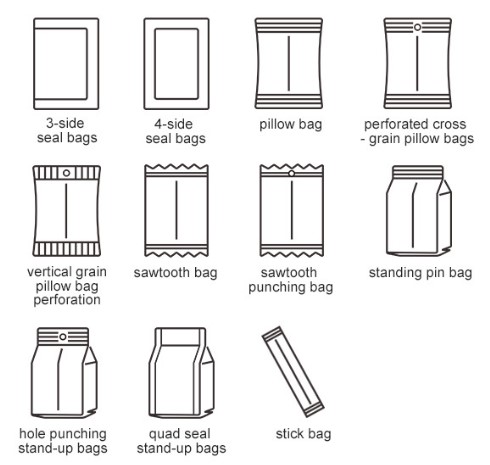

Customizable Packaging Styles: Supports multiple bag styles such as pillow bags, gusseted bags, and stand-up pouches, catering to diverse packaging needs.

VFFS machines are widely used in various industries, including:

Food Industry: Packaging snacks, coffee, spices, frozen foods, and pet food.

Pharmaceuticals: Packaging powders, tablets, and capsules.

Cosmetics and Personal Care: Packaging lotions, creams, and gels.

Chemical Industry: Packaging detergents, fertilizers, and other chemical products.

Efficiency: Automates the packaging process, reducing labor costs and increasing throughput.

Space-Saving Design: The vertical orientation requires minimal floor space, making it suitable for facilities with limited space.

Enhanced Product Protection: Provides airtight seals that protect products from moisture, oxygen, and contaminants, extending shelf life.

Cost-Effective: Utilizes rollstock film, which is more economical than pre-made pouches, leading to material cost savings.

Investing in a VFFS Packaging Machine can significantly improve your packaging efficiency, product quality, and overall operational productivity.